Excellence Is Not a Destination, but a Journey

In my previous article on operational excellence, we met Shigeo Shingo and examined the model he developed in detail. However, as I began to explore the implementation steps, I realized something important: we had not yet clearly defined what excellence itself actually is.

So, what is excellence? How do Plato’s ideas—one of the most powerful treatments of the concept of excellence in history—relate to the philosophy of operational excellence? And who first coined the term operational excellence in history? Let’s explore together.

What is Excellence?

Excellence is the state or process of reaching the highest quality, the best condition, or a superior standard. This concept goes beyond mere flawlessness—it encompasses continuous improvement, striving toward the ideal state, and realizing one’s full potential at the highest level.

Characteristics of Excellence:

- Continuity: Excellence is not static; it is a dynamic process that always aims to move one step further.

- Consistency: Achievements should not be one-time results—they must be sustainable and repeatable.

- Above Standard Quality: Excellence implies a level of performance that exceeds the average or merely acceptable.

- Integrity: Excellence includes harmony and integrity both in processes and in results.

“It is not enough to do your best; you must know what to do, and then do your best.”

W. Edwards Deming

What Is Excellence According to Plato?

For Plato, true excellence is not found in the physical world but in the world of ideas—a realm that is eternal, unchanging, absolute, and perfect.

Theory of Forms (Ideas)

According to Plato, everything—including beauty, goodness, justice, courage, and even a chair—has its own ideal and perfect form.

What we perceive with our senses are merely shadows, incomplete reflections of these forms.

Excellence = Closeness to the Ideal

For Plato, the excellence of something is measured by how closely it approximates its ideal form.

- The more a ruler approximates the idea of justice, the more excellent the ruler is.

- The more a work of art reflects the idea of beauty, the more excellent the artwork is.

“Observe, listen, be silent, judge little, ask much.”

Plato

Parallels Between Plato’s View of Excellence and Operational Excellence

Approaching the Ideal = Continuous Improvement

Plato’s concept of striving toward ideal forms aligns with the modern business principle of continuous improvement (Kaizen).

A factory or process is as excellent as it gets closer to an “ideal process design” (zero waste, no defects, fast). However, perfection is never fully attained—development is infinite.

| Plato’s Philosophy | Operational Excellence Equivalent |

| Approaching the ideal | Continuous improvement, zero defects, lean processes |

| Harmony of the soul | Organizational harmony, cross-layer synergy |

| Governance with wisdom/justice | Ethical leadership, transparent decision-making, trust |

| Seeking essence | Data- and process-driven management |

| Education and virtue | Competence development, cultural transformation |

“Excellence is not a destination achieved, but a continuous journey.”

Historical Development of Operational Excellence

Total Quality Management (TQM) (1950–1980)

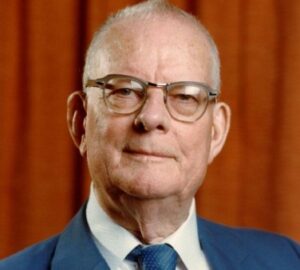

From the 1950s to the 1980s, TQM aimed to improve quality across all areas of a company and focused on customer satisfaction. The work of quality experts such as W. Edwards Deming and Joseph Juran defined this era.

Edwards Deming (1900–1993)

Edwards Deming (1900–1993)

A leading figure in modern quality management, Deming had a profound global impact—particularly in process improvement, TQM, and operational excellence. He played a crucial role in Japan’s post-war industrial success and is synonymous with the quality revolution.

| Category | Information |

|---|---|

| Lifespan | October 14, 1900 – December 20, 1993 |

| Nationality | American |

| Education | Studied physics and mathematics |

| Fields of Expertise | Statistics, quality management, process management |

| Achievements | Known as the person who transformed Japanese industry |

Deming’s Impact on Japan

- 1950s Visit: Invited by the Japanese government to train engineers and managers.

- PDCA Cycle: Helped firms in Japan systematically manage quality using the Plan-Do-Check-Act cycle.

- Recognition: The Deming Prize, established in 1951 in his honor, is one of the most prestigious quality awards.

Key Principles:

- PDCA Cycle

- 14 Points for Management

Though Deming did not directly use the term “operational excellence,” his teachings laid the foundation for today’s OPEX philosophy.

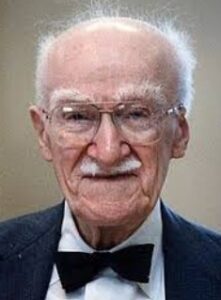

Joseph M. Juran (1904–2008)

Juran was a visionary in quality management, contributing greatly to TQM and process improvement. He viewed quality not just as a production issue but as a strategic concern throughout the organization.

| Criteria | Information |

|---|---|

| Lifespan | December 24, 1904 – February 28, 2008 |

| Nationality | American |

| Education | University of Minnesota – Electrical Engineering |

| Fields of Expertise | Quality management, process improvement, leadership |

1954 Visit to Japan

- Invited by the Union of Japanese Scientists and Engineers (JUSE)

- Was the first to provide executive-level quality education in Japan

- Sparked a cultural transformation by declaring, “Quality planning is not just the job of engineers; it is the responsibility of top management.”

Tangible Impacts

- Japanese firms adopted his strategies into business planning (Juran Trilogy)

- Companies like Toyota, Sony, and Panasonic applied his principles to become global quality leaders

Kaoru Ishikawa (1915–1989)

| Criteria | Information |

|---|---|

| Lifespan | July 13, 1915 – April 16, 1989 |

| Nationality | Japanese |

| Education | University of Tokyo – Chemical Engineering |

| Fields of Expertise | Quality management, quality improvement strategist |

Ishikawa Diagram (Fishbone / Cause-and-Effect Diagram)

- Developed in 1943

- A tool for systematically analyzing all possible root causes of a problem

- Known as the “fishbone diagram” due to its shape

In our next article, we will explore the Toyota Production System (TPS) and its founders as a continuation of the operational excellence journey.

Final ;

Viewing excellence not merely as a goal but as a journey reflects a shared perspective between Plato’s ideal forms and the philosophy of operational excellence. From Shigeo Shingo’s systematic methodology to the quality revolutions sparked by Deming and Juran, and Ishikawa’s root cause analysis—this journey shows us that true operational excellence requires not only technical application but also a profound philosophical perspective.

References ;

–https://plato.stanford.edu/entries/plato/

–https://asq.org/about-asq/who-we-are/bio_ishikawa

https://goleansixsigma.com/fishbone-diagram-aka-cause-effect-diagram/

–https://www.qualitygurus.com/kaoru-ishikawa-biography/

-Gino Crescoli – Pixabay

-Eiji Kikuta – Pixabay